How To Detect Gas Leakage From LPG Cylinders

What are the risks of LPG gas leakage?

LPG(liquefied petroleum gas) is very flammable due to the presence of gases like propane and butane present in its chemical composition, both of which when combined, compromise almost 60-80% of the total LPG mixture.

These gases pose a significant explosion or fire hazard risk, so it is very important to be able to detect when these gases start leaking. Ensure that you store these cylinders in an area that would make it easy to contain the fire and not cause a lot of damage to your assets as well as other people.

Why does LPG leakage occur?

There are innumerable reasons that could have caused your LPG gas leakage this also includes statistical anomalies, however, These are some of the major causes for gas leaks that you can actually control for:

1) Damaged or corroded cylinder valves or regulators:

Cylinder valves and regulators are typically made of brass, stainless steel, or aluminum, these are very corrosion-resistant materials. However, exposure to moisture, chemicals, or other corrosive substances can cause corrosion to occur over time. They can also be defective due to operational inefficiencies of the manufacturer.

How to fix: The expected lifespan of most cylinder valves and regulators is typically several years(varies depending on what material you use and the brand), and they should be inspected and maintained at regular intervals of at least 6 months to ensure their proper functioning.

2) Improper LPG installation:

LPG installation is a fairly complex procedure and it involves various steps, improper installation by inexperienced or untrained people can cause leakage of LPG.

How to fix: Either properly train yourself to do LPG installations or hire an expert who is able to do this task perfectly, Always check the credibility of the professional that you are trying to hire using their reviews and other such indicators.

3) Overfilling of Cylinders:

Sometimes even due to small statistical outliers cylinders can be overfilled by the LPG cylinder suppliers. Since the cylinder has a specific capacity exceeding it can easily cause leakage.

How to fix: Always ensure that every single LPG cylinder you are buying is not overfilled through inspections.

4) Physical damage to the cylinder:

Again even due to small statistical outliers, certain cylinders could be poorly made and get easily damaged. This will decrease their carrying capacity and cause them to overfill much more easily than a normal cylinder.

How to fix: Try to buy your LPG cylinder from a reputed source to reduce statistical risk and also always manually inspect all your cylinders.

Methods for detecting LPG gas leakage:

1) Smell:

If you smell gas, it’s essential to immediately turn off the gas supply this is so because a distinct odorant is added to LPG to make it easily detectable in case of any gas leaks.The odorant used in LPG is usually a chemical called Ethyl Mercaptan, which has a strong and unpleasant smell similar to rotten cabbages or rotten eggs. Ethyl Mercaptan is added to LPG in minimal amounts, typically around 25.14 parts per million (ppm), which is enough to make the gas easily detectable by the average human nose.

The smell test should only be used in a domestic setting and as a supplementary detection measure. In a commercial or industrial setting it is hard to tell where the smell is coming from due to the large number of cylinders they have to work with and also it is hard to tell if the smell is from leakage or something else.

2) Electronic Gas detectors:

Electronic gas leak detectors are highly sensitive and can detect even small amounts of gas in the air. These devices use sensors and can detect the presence of LPG in the air. There are two types of gas detectors: portable and fixed gas detectors, both with different uses.

Fixed gas detectors are used for single locations with high activity with various gases and are controlled through a centralized mechanism, while portal gas detectors are used by individuals to detect any dangerous gas that might be present in their localized environment. Portable gas detectors are typically battery-powered, making them easy to use in different locations. Fixed gas detectors can be connected to a control panel or building automation system for centralized monitoring in a corporation that can afford sufficient staff.

It’s important to note that electronic gas leak detectors should be regularly maintained and calibrated to ensure their accuracy and reliability. In addition, they should be used in conjunction with other safety measures, such as regular inspections and maintenance of gas systems.

Domestically you can use both fixed and portable gas detectors though for a house fixed gas detectors are recommended as they can cover the entire house with ease while personal gas detectors might not have that range.

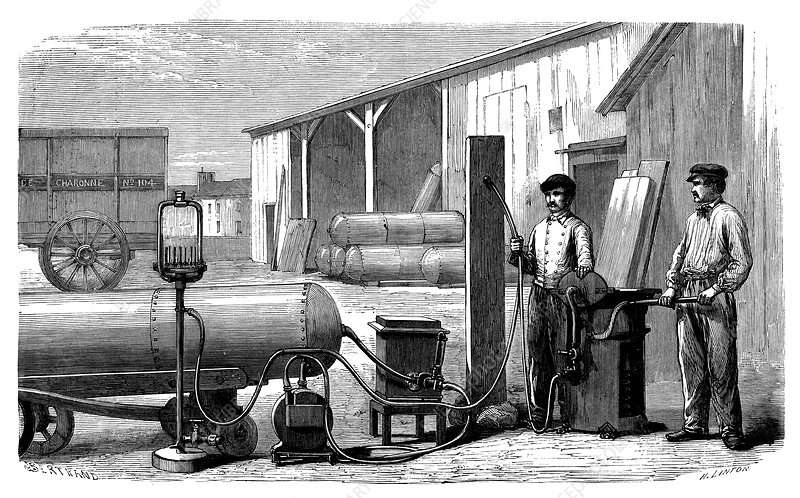

3) Soap and water solution:

A simple soap and water solution can be applied to the surface of the various devices you use for transmitting gas from a cylinder like a hose or a pipe. Start pressurizing the cylinders to send the gas through the transmitting device and if there is any leakage, bubbles will start to form at that site.

Bubbles get formed because of the gas that leaves the pipes or valves connected to a cylinder which gets covered by the molecules of the soap solution and the molecules of the soap solution also start to minimize their surface tension and form a circular shape.

Conclusion:

While the detection of LPG leakage is extremely important, Like all sorts of situations the focus should primarily be on the prevention of the occurrence of leakage in the first place.