The Role of Greenhouse and LPG in Combating the Global Food Crisis

What are greenhouses?

Greenhouses are really cool structures that are designed to help plants grow and thrive, no matter what the weather is like outside; they have become extremely important due to the growing climate change concern. They’re like giant, climate-controlled environments that provide the perfect growing conditions for all kinds of plants. This helps countries and other entities like NGOs to grow essential crops and plants in remote regions of the world.

Imagine a big, glass house filled with lots of different plants, from tiny seedlings to towering trees. The walls and roof of the greenhouse are made of special glass that lets in sunlight, providing the energy plants need to grow. The greenhouse is also insulated to help trap heat, so the temperature inside stays warm and cozy for plant growth, even in especially cold climates.

In addition to food production, greenhouses also play an important role in scientific research and education. Botanists and scientists use them to study plant growth and development, as well as to conduct experiments on plant breeding and genetics. Greenhouses also provide an opportunity for students and the public to learn about plants and agriculture in a hands-on, interactive way.

Origins of the Greenhouse

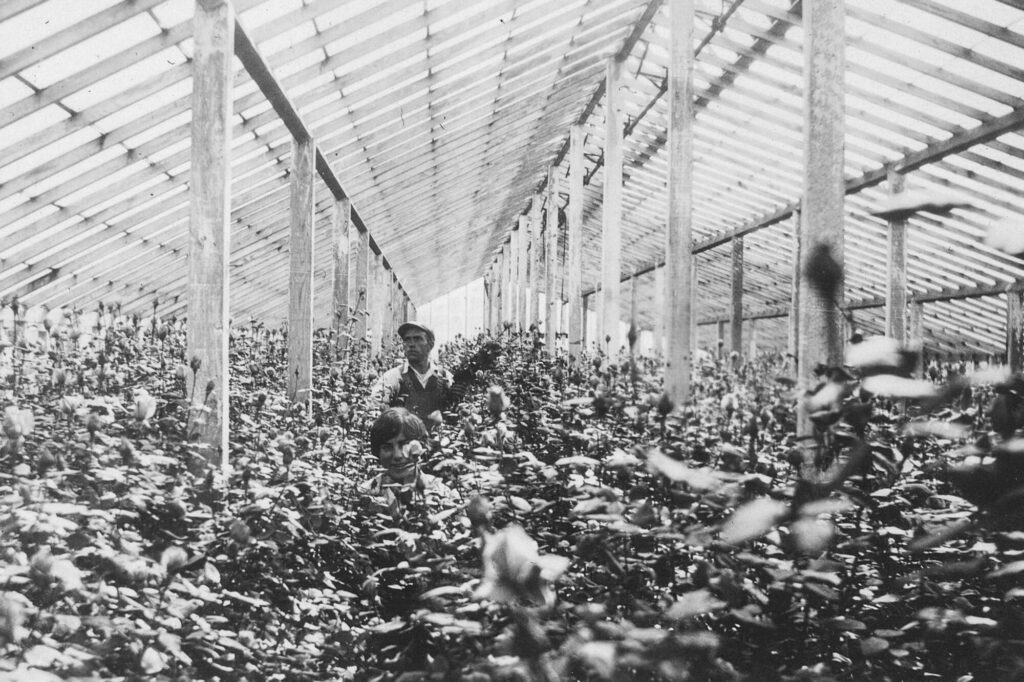

Greenhouses have come a long way since their early days in ancient civilizations. The idea of using structures to control the environment for plant growth has been around for thousands of years, but advancements in materials, technology, and design have made modern greenhouses highly advanced structures that provide ideal growing conditions for plants.

In ancient times, greenhouses were constructed using locally available materials such as clay, wood, and glass. The construction of greenhouses varied depending on the location and climate, with an emphasis on maximizing sunlight, ventilation, and insulation to create a protected environment for plants to grow.

In the Renaissance period in Europe, wealthy landowners began constructing “orangeries,” which were large buildings with large windows or glass roofs used to cultivate citrus trees and other exotic plants. These orangeries were precursors to modern-day greenhouses, providing controlled environments to grow plants outside of their natural growing season and climate.

In the 19th century(during the Victorian era, which lasted from 1837 to 1901), with the introduction of new materials such as wrought iron, plate glass, and cast iron, the modern greenhouse as we know it today was developed. These materials allowed for the construction of larger and more stable structures, which could be heated and ventilated more effectively.

Today, greenhouses are highly advanced structures that incorporate the latest technology in heating, cooling, ventilation, and environmental control. The design of modern greenhouses is based on optimizing the growing environment for specific crops, with features such as automated shade systems, computer-controlled irrigation, and lighting systems that mimic natural sunlight.

Advancements in materials science have also led to the development of new types of greenhouse coverings, such as polycarbonate and acrylic, which are lighter, more durable, and more energy-efficient than traditional glass. These new materials also allow for greater flexibility in greenhouse design, making it possible to construct structures of almost any size or shape.

How does LPG play a role in a Greenhouse?

LPG, or liquefied petroleum gas, is commonly used to heat greenhouses. It is a clean-burning fuel that produces a lot of heat, making it an ideal choice for heating large spaces like greenhouses. The preferred LPG mix for heating greenhouses is typically that which consists of a much higher composition of propane in the total gas mix.

Propane is typically preferred over butane as the primary component in LPG for heating greenhouses. This is because propane has a lower boiling point than butane, which means it can be more easily vaporized and burned efficiently in greenhouse heating systems. In addition, propane has a higher heat content than butane, which means it can provide more heat per unit of fuel than butane. This makes propane a more efficient fuel source for heating greenhouses and can help to reduce energy costs.

While butane can also be used as a component in LPG for heating greenhouses, it is generally considered to be less efficient than propane, particularly in colder weather conditions. Butane has a higher boiling point than propane, which means it can be more difficult to vaporize and burn efficiently in colder temperatures.

LPG is typically stored in tanks located outside of the greenhouse, and a network of pipes and hoses is used to transport the fuel into the greenhouse. Inside the greenhouse, LPG heaters are used to produce heat that is distributed throughout the space.

LPG heaters come in a variety of sizes and styles, depending on the size of the greenhouse and the specific heating needs of the crops being grown. Some heaters are designed to be suspended from the ceiling, while others are placed on the ground or mounted on walls.

One advantage of using LPG to heat greenhouses is that it can be easily controlled and adjusted to maintain a consistent temperature. Many LPG heaters are equipped with thermostats that automatically turn on and off as needed to maintain the desired temperature.

Another advantage of using LPG is that it is a relatively affordable and efficient fuel source. LPG heaters are typically more efficient than electric heaters, which can help reduce energy costs and make greenhouse operations more cost-effective.

Conclusion

Greenhouses are important because they allow us to grow crops and plants in controlled environments, providing protection from the elements and enabling us to cultivate a wider variety of plants and produce, including exotic and seasonal crops. LPG is important in greenhouses because it is a clean and efficient fuel source that can be easily controlled to provide consistent heat to plants. Greenhouses require a stable and consistent temperature to ensure optimal growing conditions for the plants, and LPG provides a reliable source of heat that can be easily adjusted to meet the specific needs of the plants.