In this article, we will delve deeply into why cylinders exist in the form that they currently do as well as their brief origins.

Origins of cylinders:

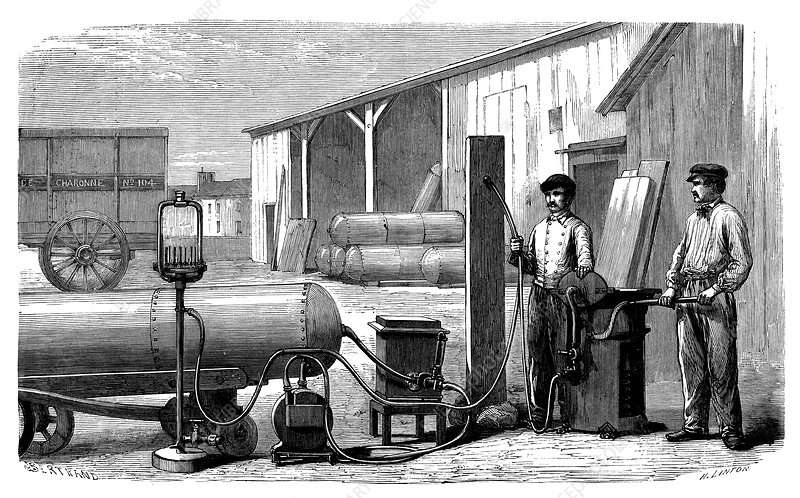

The use of cylinders dates back to the 19th century when the use of compressed gas rapidly increased due to its efficiency, reliability, and safety in providing heating as well as lighting to people back then, Cylinders were invented to store compressed gas in a very economical and efficient way.

The very first cylinders in the market were either made of wrought iron or steel and they were mainly used for storing coal gas. Later, in the early 20th century, Aluminum cylinders grew in popularity as these cylinders were tougher and more durable than the cylinders used before. Aluminum cylinders are also lighter and more corrosion-resistant than the older cylinders, Further, this makes them more convenient to transport and handle, and they also have a longer lifespan.

The development of welding techniques also made it possible to manufacture cylinders with seamless walls, which improved their strength and safety. Today, cylinders are used for storing and transporting a wide range of gases and liquids, including propane, oxygen, helium, and nitrogen, among others.

The use of cylinders has also revolutionized many industries, including healthcare, welding, and manufacturing, among others. Cylinders have played a crucial role in space exploration and scientific research, where they are used for storing and transporting gases and liquids in a zero-gravity environment. The use of cylinders is expected to continue to grow as more applications are found for pressurized gases and liquids in various industries.

Why are cylinders cylindrical in shape?

The cylindrical shape is considered the best shape for gas cylinders for several reasons:

1) Strength: The cylindrical shape provides the best strength-to-weight ratio compared to other shapes. The circular cross-section of the cylinder allows for an even distribution of stress and pressure, which makes it ideal for containing compressed gas. Other shapes, such as rectangular or spherical, can have weaker points where stress and pressure can concentrate, making them more prone to failure and leading to higher costs on average for companies and customers.

2) Efficiency: The cylindrical shape has the lowest surface area when compared to other shapes of the same volume which means it provides the most efficient way to store compressed gas as it requires less material to build the same container.

3) Stability: The cylindrical shape is inherently stable and less prone to tipping over, making it easier to store and transport. This is particularly important for gas cylinders, which can be hazardous if not handled correctly and can cause a company millions of dollars in lawsuits.

4) Manufacturability: The cylindrical shape is also easier to manufacture compared to other shapes. Cylinders can be produced by rolling a flat sheet of metal and welding it into a cylindrical shape. Other shapes, such as spheres or complex geometries, require more complex manufacturing processes and therefore a more training for the workforce which can lead to escalating costs for a manufacturing company.

In summary, the cylindrical shape is considered the best shape for gas cylinders due to its strength, stability, efficiency, and ease of manufacture. While other shapes may have certain advantages in very specific areas of applications, the cylindrical shape provides the best general utility due to its practical and efficient design for storing and transporting compressed gas.

Why are there cylinders in different colors?

Cylinders used for storing and transporting gases are often painted in bright colors to indicate the type of gas they contain, to help prevent accidents, and ensure the safety of people that might be handling them. In many countries, including the United States, Canada, and Europe, the color code for gas cylinders is standardized and regulated by law so it is a legal requirement in many cases.

The standard color for a gas cylinder containing flammable gases, such as propane and butane, is red. The red color is intended to provide a warning to users and handlers that the cylinder contains a flammable gas, which can pose a potential risk of fire or explosion. Red light has the longest wavelength in the visible spectrum, which means it can penetrate through fog, dust, and other particles in the atmosphere more effectively than other colors. This makes it more visible at a distance and in low-light conditions.

Cylinders containing other types of gases, such as oxygen, nitrogen, and argon, are painted in different colors to help identify their contents easily. For example, oxygen cylinders are typically painted in green, nitrogen cylinders in black, and argon cylinders in dark blue. This makes it easier for companies to handle inventory management as well as logistics and also reduces error by workers when working with these types of cylinders.

It’s important to note that the color code for gas cylinders can vary slightly in different countries or regions, and the information provided here is just a general guideline. It’s always essential to follow the safety regulations and guidelines established in your area and to handle gas cylinders with care and caution.