Introduction

LPG regulators play a crucial role in maintaining the safe and efficient operation of LPG systems. Regular maintenance and inspection of these regulators are essential to identify potential issues and ensure the smooth flow of gas as well as preventing any harmfull accidents like explosions or fires. In this blog, we will explore the importance of regulator maintenance and provide a comprehensive guide with more than 10 easy to use techniques to keep your LPG regulators in top-notch condition.

Regulator Techniques

Ensure that the gas supply to the regulator is shut off. This step is essential to prevent any accidental gas leaks during the inspection. ( Except for leak detection test )

1) Visual Inspection: Start by cleaning the exterior of the regulator using a soft, lint-free, and freshly washed cloth. Wipe away any dust, dirt, or grease that may have accumulated on the surface. Start by visually inspecting the regulator for any signs of damage, corrosion, or wear. If the regulator has adjustable settings for pressure control, inspect the adjustment knobs or screws. Ensure they are intact and functioning properly.

2) Vent Check: Ensure that the regulator’s vent is free from obstructions. A blocked vent can lead to pressure buildup and potential safety hazards. Use a small brush or compressed air to clear any blockages. For more stubborn blockages, especially in intricate or hard-to-reach areas of the regulator, ultrasonic cleaning can be effective

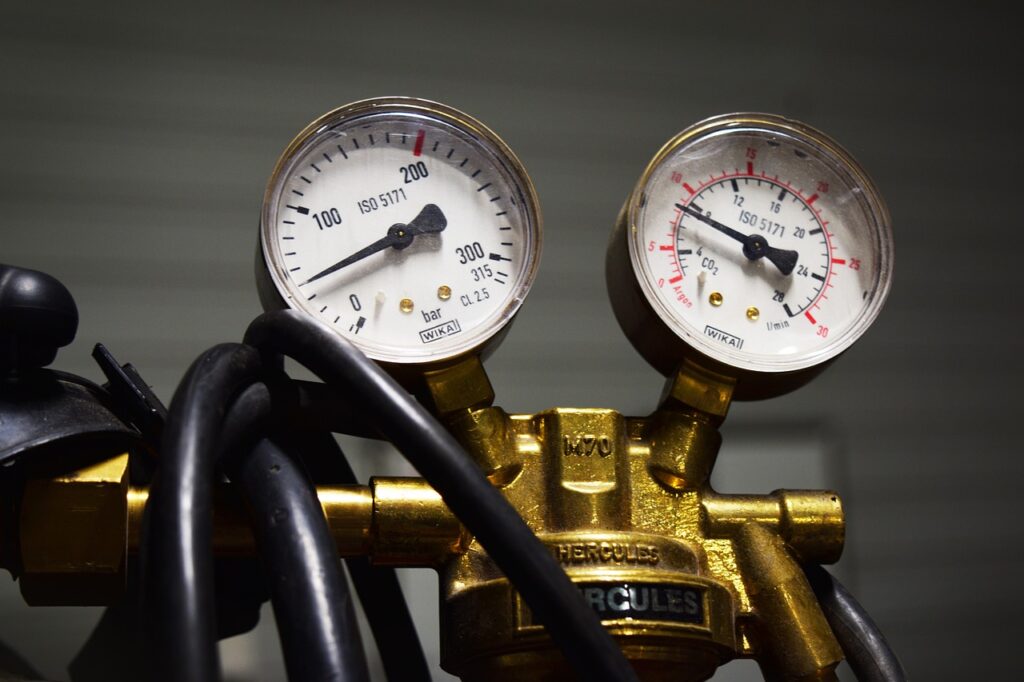

3) Pressure Testing: Perform regular pressure testing to verify the regulator’s accuracy. Connect a pressure gauge to the regulator’s outlet and compare the reading with the desired pressure. If there is a significant deviation, consider recalibrating or replacing the regulator.

4) Leak Detection: Check for gas leaks around the regulator using a gas leak detector solution or soapy water. Apply the solution to the regulator’s fittings and connections, and observe for any bubbles indicating a leak. Address any leaks promptly. For a large number of cylinders you can use electronic gas detectors to detect leak as they give off a visual or audible alarm when a leak is detected.

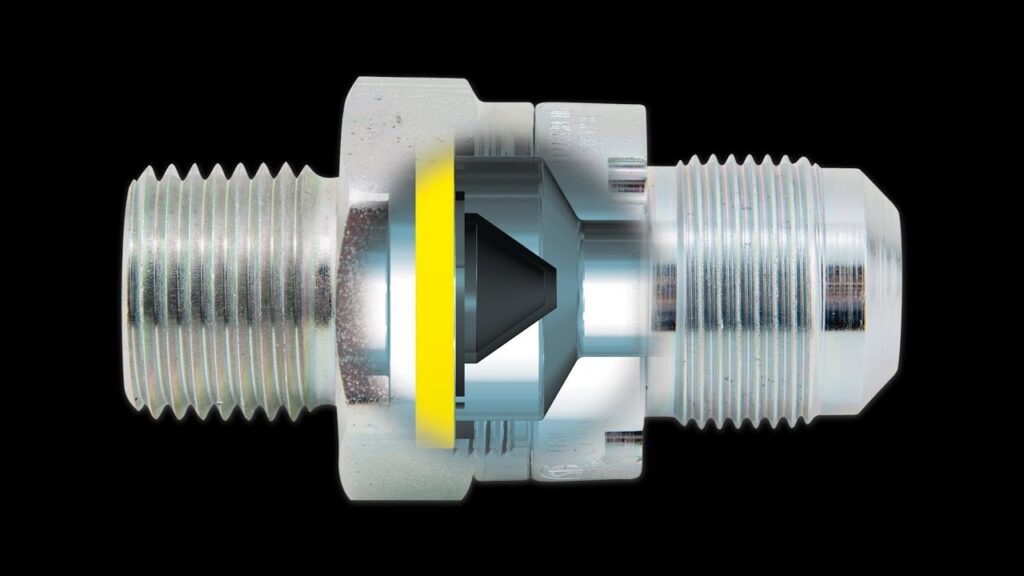

5) Diaphragm Inspection: Inspect the diaphragm, a critical component of the regulator, for signs of damage or wear. If it appears worn or deteriorated, it should be replaced.

6) Pressure Relief Valve (PRV) Testing: The PRV ensures the release of excess pressure in case of a system malfunction. Connect the regulator to a reliable LPG source or a test gas cylinder with a known pressure. Ensure that the connections are properly tightened and secure. Test the PRV by gradually increasing the pressure and ensuring it opens at the designated set point. If it fails to operate correctly, contact a professional for repairs or replacement.

7) Regulator Adjustment: Some regulators have adjustable settings for pressure control. Follow the manufacturer’s instructions to make necessary adjustments within the specified range. Avoid exceeding the recommended limits, as it may lead to unsafe operation.

8) Lubrication: Certain regulators may require lubrication for smooth operation. Inspect the regulator to identify the specific points where lubrication is required. Common lubrication points may include pivot points, O-ring seals, or any other moving parts that may benefit from lubrication. Refer to the manufacturer’s guidelines to identify the appropriate lubricant and apply it as instructed.

9) Filter Maintenance: If the regulator has an integrated filter, clean or replace it as recommended by the manufacturer. A clogged filter can impede gas flow and compromise performance. You can use compressed air cans or a brush to get rid of easier to remove debris that is clogging the filter, For more serious debris try soaking the filter in a cleaning solution.

10) Excess Flow Valve (EFV) Inspection: EFVs are safety devices that restrict gas flow in the event of a sudden surge. Periodically inspect the EFV to ensure it is functioning correctly and not obstructed. Again to clear the blockage you need to do a similar thing as before and use compressed air, brushing, or a chemical solution specially prepared to clear harder-to-reach debris.

11) Professional Inspection: While regular maintenance can be performed by the user, it is advisable to have a qualified professional inspect your LPG regulator periodically. They have the expertise to have a much higher

Conclusion

In conclusion, ensuring the safe and efficient use of your LPG cylinders necessitates proper maintenance and regular inspection of LPG regulators. By implementing these practices, you can proactively identify potential issues, prevent gas leaks, and maintain optimal functionality. It is crucial to adhere to the manufacturer’s instructions and seek professional assistance when needed. Prioritizing regulator maintenance will not only enhance the overall safety of your LPG system but also contribute to its reliability and dependability. By dedicating attention to these crucial aspects, you can enjoy peace of mind and a well-functioning LPG setup for all your needs.